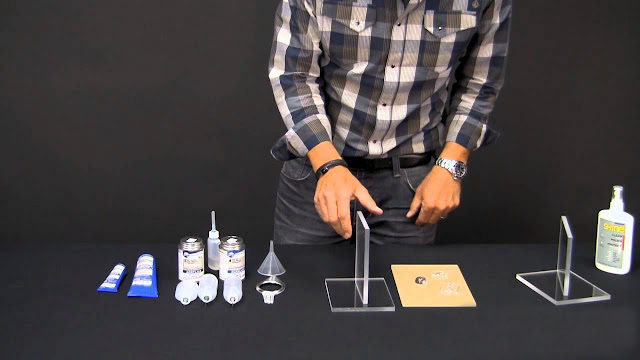

Custom Acrylic Display Stands Polishing Improving Methods

custom acrylic display stands Polishing process is important step during custom acrylic display stands production. Because this step will influence the appearance visual effect of the display stands. Actually, the result of polishing process will not only influence the visual effect of the display stands, but also will influence the display effect of your products. Normally, there are three kinds of polishing methods that are frequently using during custom acrylic display stands production. They are buffing polishing way, flam polishing way and diamond polishing way. In this article, the polishing engineer from Able Acrylic Display would like to discuss about these polishing ways. First, buffing polishing way. This is the mostly using polishing way for custom display stands. When polishing acrylic display stands , we will need to put some polishing wax on the buffing machine. Then let the acrylic board press onto the buffing gently and move the acrylic board ...